The Starter Kit That's More Than a Starter Kit!

IIoT and Industry 4.0 ready, this kit is more than just a starter!

This powerful package contains all the hardware you need to get started with Internet of Things (IoT) projects as well as advanced introductions into IIOT - You won’t be left behind in your PLC learning journey.

Features of this Kit:

-

You’ll be ready for anything in BCS Tools/CODESYS with respect to IEC 61131-3 programming languages for PLCs.

-

You'll be able to work with any X2 HMI, on top of knowing how to configure and design applications, with iX developer software.

-

With the Nexto Xpress you’ll gain experience with dealing with all the common IO types for PLCs. Including AI, AO, DI, DO and RTDs.

-

Your experience in communication protocols will grow, including ethernet IP, modbus TCP and RTU, CANopen/CAN bus and J1939, OPC UA, MQTT, and SQL server integration.

Includes:

X2 base 5 v2

The X2 base v2 panels are cost-effective industrial HMIs with high-resolution touch-screens and modern design. The HMIs combine IP65 corrosion resistant plastic housing with the full version of the iX software, providing a cost-effective yet advanced HMI solution for small to medium applications.

Features:

-

5" Screen. 800 × 480 pixel (5:3)

-

TFT-LCD touch screen

-

500 MB application memory

-

1 × Ethernet, 4 × serial, 1 × USB as standard

-

Operating temperature -10° to +50° C

-

CE, FCC, KCC, CUL

OR

X2 base 7 v2 HP

Features:

-

5" Screen. 800 × 480 pixel (5:3)

-

TFT-LCD touch screen

-

1.5 GB application memory

-

2 × Ethernet, 6 × serial, 2 × USB as standard

-

Operating temperature -10° to +50° C

-

CE, FCC, KCC, CUL

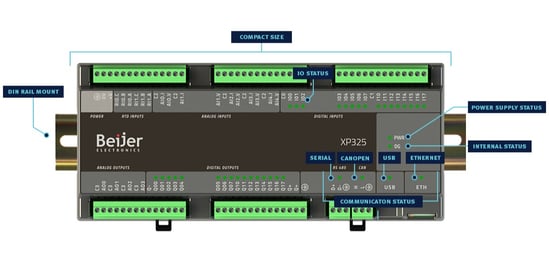

Nexto Xpress XP325 PLC

Nexto Xpress features DIN-rail mount, compact design, high-speed 32-bit ARM-based processor, high I/O density with multi-purpose analog inputs, LEDs for diagnostics and IO status, and real-time clock.

Features:

-

IO: 16DI, 16DO, 5AI, 2RTD, 4AO

-

Industry 4.0 ready by connectivity via OPC UA.

-

Cost-efficient in a compact format offering the perfect mix of digital and analog I/Os.

-

Perfect within machinery, building automation, water and waste water, infrastructure, etc.

-

Same powerful CODESYS programming environment for all Nexto controllers

-

Wide range of connectivity options using standard industrial protocols

-

Built-in high speed I/O for precise machine control.

-

Interface with other equipment via integrated CAN bus

OR

Nexto Xpress XP340 PLC

Features:

-

IO: 16DI, 16DO, 5AI, 2RTD, 4AO

-

3G/4G/WiFi (external accessory via USB port)

-

SQL integration

-

WebVisualization, IEC 60870-5-104-server

-

Industry 4.0 ready by connectivity via OPC UA.

-

Perfect within machinery, building automation, water and waste water, infrastructure, etc.

-

All Features from XP325

AND

JetNet 2005-w

Korenix JetNet 2005 is an Industrial 5-port 10/100BaseTX Ethernet switch. 2005 adopts slim industrial design to save rail space for compact systems. In order to survive under harsh environment, JetNet 2005 features an industrial-grade aluminum case with against dust and water.

iX Developer

Are you ready to modernize your operator interface?

iX empowers you with modern tools to communicate. The software combines top-class graphics and smarter functions that provide intuitive operation on the spot. Not to mention the almost limitless connectivity to your other equipment through the extensive list of drivers.

BCS Tools Lite

The all-in-one development platform for control and PLC programming

BCS Tools is the CODESYS-based software platform for IEC 61131-3 compliant project engineering of all controllers and PLCs in our product range.

BCS Tools includes numerous user-friendly functions for your control and PLC programming and configuration of automation projects and contains fully integrated back-end functions, such as compilers, debuggers and variable trace. Using BCS Tools, an application can be developed, tested and commissioned without any additional tools.

One software. Endless possibilities.

.png?width=109&height=111&name=mica-controls-honeycomb-logo-150x67@2x%20(1).png)

.png?width=550&height=257&name=Jetnet2005%20(1104%20%C3%97%20516%20px).png)

%20(1100%20%C3%97%20520%20px)-1-1.png?width=160&height=225&name=Jetnet2005%20(603%20%C3%97%20350%20px)%20(1100%20%C3%97%20520%20px)-1-1.png)