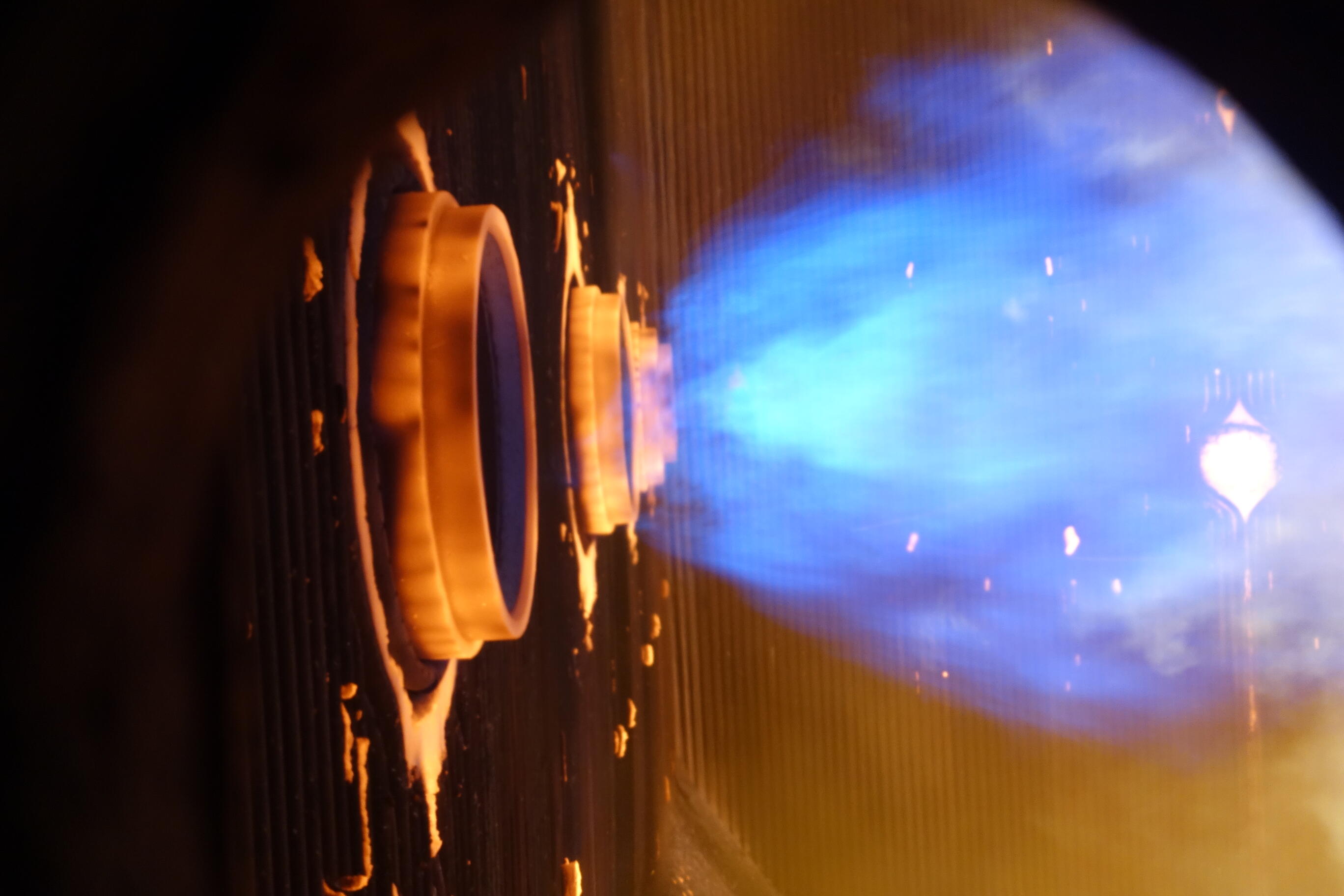

Power Burners

With a patented technology that enhances fuel staging and free jet mixing, Zeeco’s power burner reduces emissions in some applications to single-digit numbers. The company has been engineering an evolution of burners since steam generation began requiring it over seventy years ago with unparalleled results already at hand for industries like these demanding high performance from their equipment while maintaining strict safety standards too!

Free-Jet Power Burner

The Evolution of Innovation

-

Operates on refinery gas, natural gas, or dual fuels, such as fuel oils

-

9 ppm NOx, sub-50 ppm CO with minimal external flue gas recirculation (EFGR)

-

30 ppm NOx potential with no EFGR

-

Smaller fans mean less electricity and lower CO2 for a green combustion operation

Boiler Burners

ZEECO boiler burners are used to produce heat and steam across a wide range of industries – from refineries and petrochemical plants to power plants and pulp and paper. Advancing long-proven boiler burner designs is nothing new for Zeeco. They've helped to transform the emissions-heavy, fuel-draining burners of yesteryear into clean, energy-efficient systems that enable industries to increase boiler capacity, introduce new fuel additions or convert to less costly fuels, and reduce CO2.

Duct Burners

From the largest utility gas turbine to the most challenging duct burner applications, ZEECO duct burners deliver stable, reliable, and low emissions over a wide range of firing conditions. Each duct burner system is specifically engineered to provide supplementary firing for heat recovery steam generators (HRSG), Flue Gas preheat for Selective Catalytic Reduction (SCR), Combined Cycle / Co-Gen, or other air heating applications.

TEG+

The next generation ZEECO TEG+ Duct Burner provides the most reliable supplementary firing system available for today’s demanding HRSG and Turbine Exhaust Gas (TEG) applications. Our self-supporting burners eliminate the need for internal fixed structural support, which can cause binding and overall deformation – dramatically reducing installation time and material costs. TEG+ burners use flame stabilizers featuring an optimized drilled wing orifice pattern to create a short, compact flame. The nozzle design features pilot flame propagation drilling and varying orifice sizes throughout the runner to ensure highly reliable ignition, even temperature distribution, and consistent flame pattern.

Register-Style

ZEECO register-style duct burners may be the ideal choice when lower emissions or lower operating O2 levels are a project requirement. Our register-style duct burner delivers high efficiency and excellent reliability across a wide range of both gaseous and liquid fuels, suitable for a variety of TEG firing applications.

PDH Air Heaters

Propane Dehydrogenation (PDH) regeneration air heaters must operate reliably through extreme gas velocities, high heat releases of up to one billion Btu/hr, fuel composition variations, temperature/pressure fluctuations, and more. Zeeco’s robust vessel, burner, and mounting system design deliver dependable results in harsh conditions and provide lower emissions, improved reliability, and exceptional flexibility for the long term.

.png?width=259&height=111&name=LOGO%20technologies%20v2%20(5).png)

_IMG_2095-CMYK-1.jpeg?width=1132&height=1041&name=GB%20Power%20Burner%20(2)_IMG_2095-CMYK-1.jpeg)